Plastic Metal pays a lot of attention to the energy consumption of its plastic moulding machines: lower consumption is equal to less energy costs and less pollution

The search for alternative, ecological and safe energy sources is certainly an important objective for every nation.

But what we can all do, right now, is to reduce energy demand using now-a-days technologies.

Plastic Metal has been producing energy-efficient injection moulding machines for years, the technology is reliable and allows to see the results of energy and economic savings immediately.

Currently, the electricity that we consume comes mainly from fossil fuels (coal and oil) whose combustion process in power plants releases large amounts of CO2 (carbon dioxide) and highly polluting gases into the atmosphere.

Nuclear power is the other source of electricity production, with minimal pollution, but with the problem of the radioactive waste management.

With the exception of renewable energy sources – which do not pollute directly – the effects of electricity consumption are many, both for the environment and for the health of the ecosystems.

HOW MUCH INDUSTRIAL ACTIVITY AFFECTS THE ENERGY CONSUMPTION?

The sources report slightly different data depending on the parameters used in the calculation of the statistical data; however, we can refer to the official data released by CCEE, UNEP and SE4ALL.

A report, by the Copenhagen Centre on Energy Efficiency and by UNEP and with the support of the SE4ALL campaign (Sustainable Energy for ALL) of the United Nations, reveals that 29% of all energy consumed on a worldwide level is related to the industrial sector.

The same study also indicates that, with the current available technologies, in the industrial sector it’s possible to reduce the energy consumption up to the 73%.

THE ENERGY CONSUMPTION GROWTH INDEX

According to the Statistical and Analytical Agency of the Department of Energy of the United States of America (EIA) the world energy consumption will grow by almost 50% between 2019 and 2050.

A growth that will focus mainly in the industrial sector, considering the increase in energy consumption proportionally to the increase in the consumption of goods.

Industrialized countries are the world’s largest consumers of energy: they represent 15% of the global population and consume more than 50% of the total energy.

It is therefore, up to the industrialized countries at first to act as soon as possible in order to reduce their energy needs.

WHY IS IT IMPORTANT TO USE LOW ENERGY CONSUMPTION MACHINES?

According to Terna, based on the type of activity, the electrical consumption in Italy is allocated as:

- 44.1% industry sector (125,4 TWh)

- 30,2% service sector (85,8 TWh)

- 23,3% house-hold sector (66,2 TWh)

- 2,2% agriculture sector (6,3 TWh)

The manufacturing sector, responsible for the 39% of national electricity consumption, is among the most energy-consuming sectors, followed by the metallurgy and trade ones, with a 7,4% each.

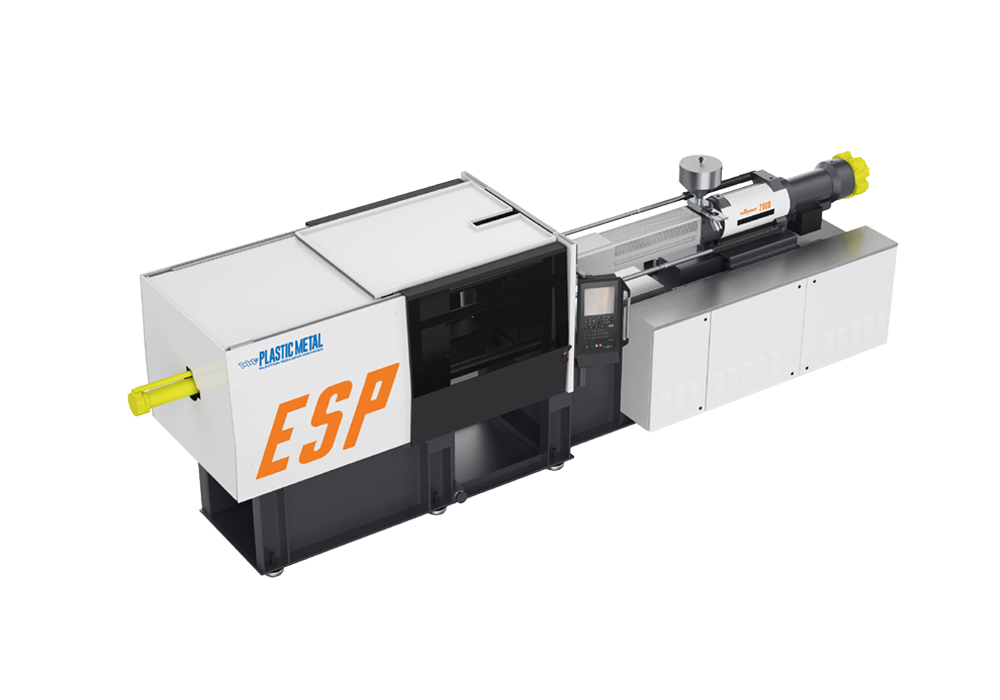

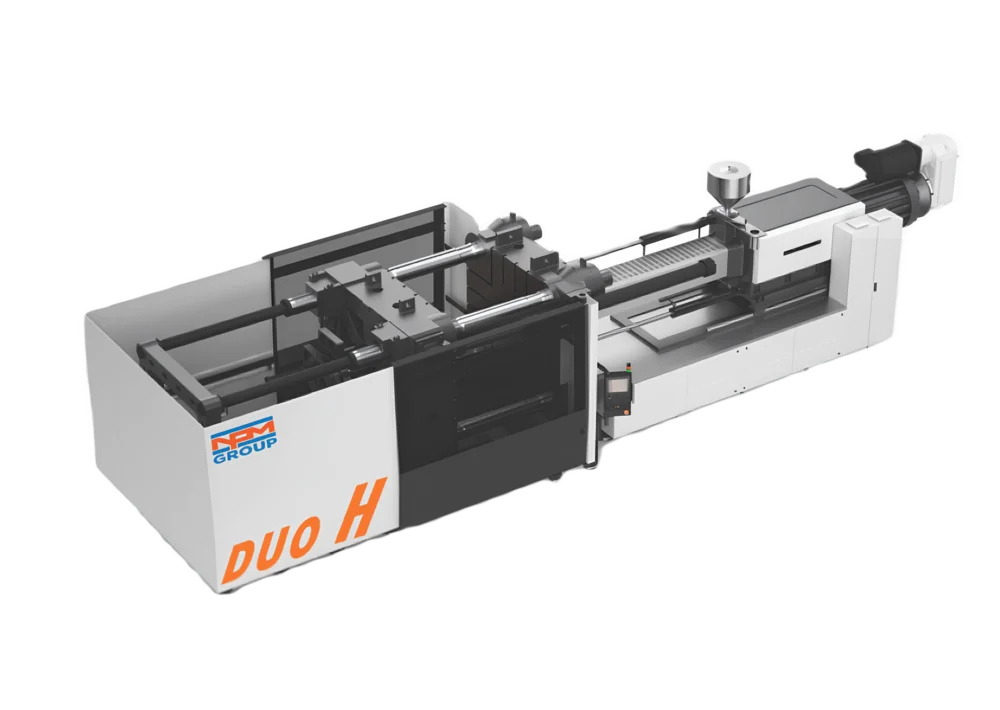

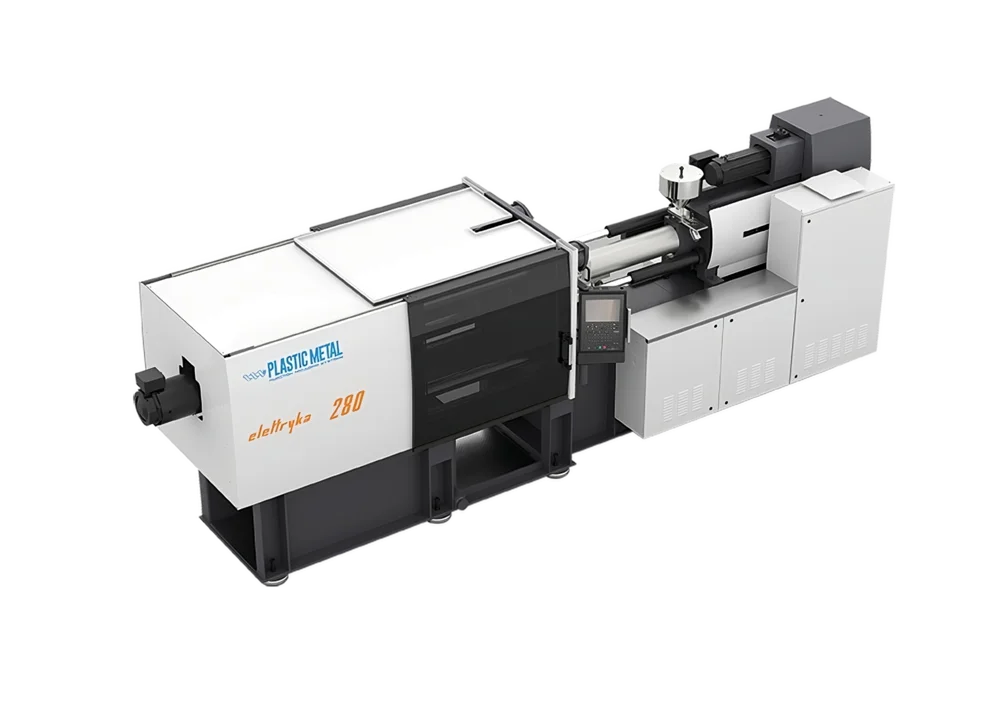

THE GREEN SOLUTIONS OF PLASTIC METAL

For over twenty years Plastic Metal has concentrated its research and development resources in energy-saving technology.

At a mediatic level only in the last years there has been a daily debate for the environment, the climate change, and the dramatic global consequences.

Even before the 2000s, Plastic Metal worked at the MULTIPOWER model, an injection moulding machine that could guarantee excellent moulding performance in terms of speed and quality of the finished product reducing at the same time the electricity consumption.

Multipower has a hybrid technology, which uses the combination of hydraulic and electric drives in an efficient way, responding to the needs of the movement itself and combining this to the most useful hydraulic or electric drive.

Over the years, thanks to constant research, the MULTIPOWER range has expanded, specializing on the moulding needs of the many market sectors, still maintaining the focus on energy savings.

Today MULTIPOWER is available in the variants HE, H, SP, DUO, HIGH TONS and of course E-FULL Electric.

Also, the designing of the system components follows the logic of energy and economic savings to use the material without having waste.

THE LOW-CONSUMPTION TECHNOLOGY OF PLASTIC METAL MACHINES ALSO AFFECTS TRANSPORT: HOW?

In 2019, energy consumption in the transport sector in Italy amounted to 39,8 Mtep, a value equal to 34.5% of the total energy consumption of the country. The highest consumptions are associated with road transport – cars, trucks, and coaches (83% of the total). The remaining percentage comes mainly from sea and air transport.

In general, in Europe, the data doesn’t change according to the European Environment Agency, transport consumes one third of the entire energy of Europe, energy that comes from petroleum and is responsible for a large proportion of greenhouse gas emissions and contributes to climate changes. Currently, transports are responsible for more than a quarter of total greenhouse gas emissions in the EU.

This makes the transport sector a major obstacle to achieving the EU’s climate protection objectives.

But what does the injection moulding machine for thermoplastics have to do with the transport sector?

The transition to a circular economy is crucial – as the PLASTICSEUROPE association says – and Plastic Metal has the technology to meet this need.

Thanks to the COINJECTION technology in fact, it is possible to reuse scrap plastic directly from its own production, without the need of moving trucks for the disposal and subsequent purchase of the recycled plastic material.

The manufacturer can recover the scrap pieces, grind them and obtain recycled material to be used in its production. This significantly reduces the time used for managing the recycled material and also the transport connected to it.

We will be back to this subject in the next articles, explaining in detail the process of coinjection.

Do you want more information on this article?

Fill out and send the form below, our specialists will contact you as soon as possible.