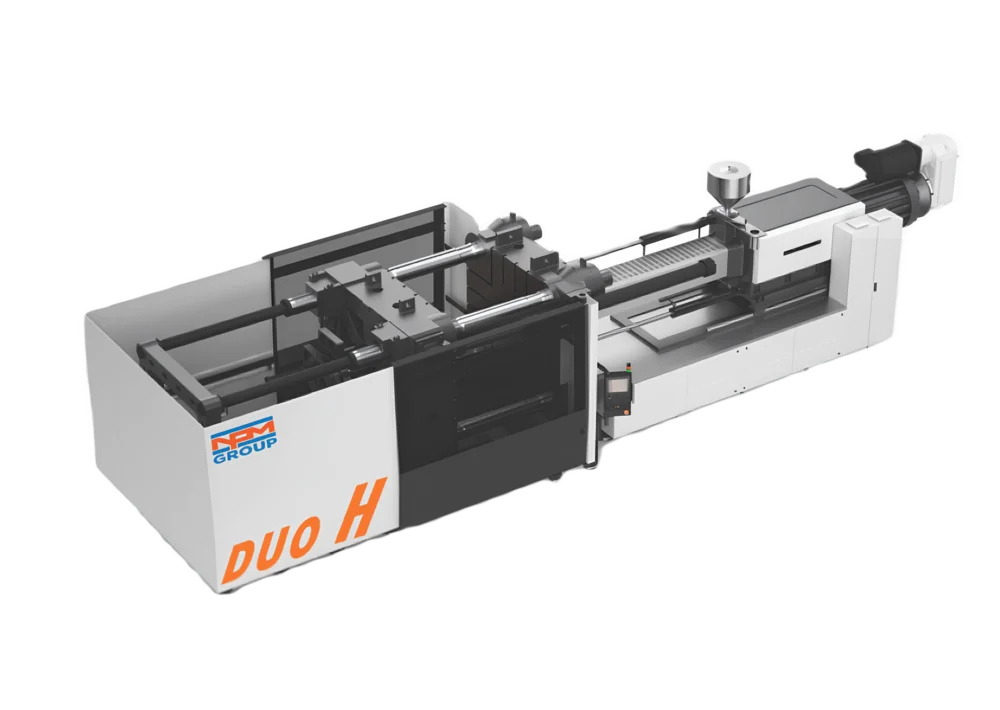

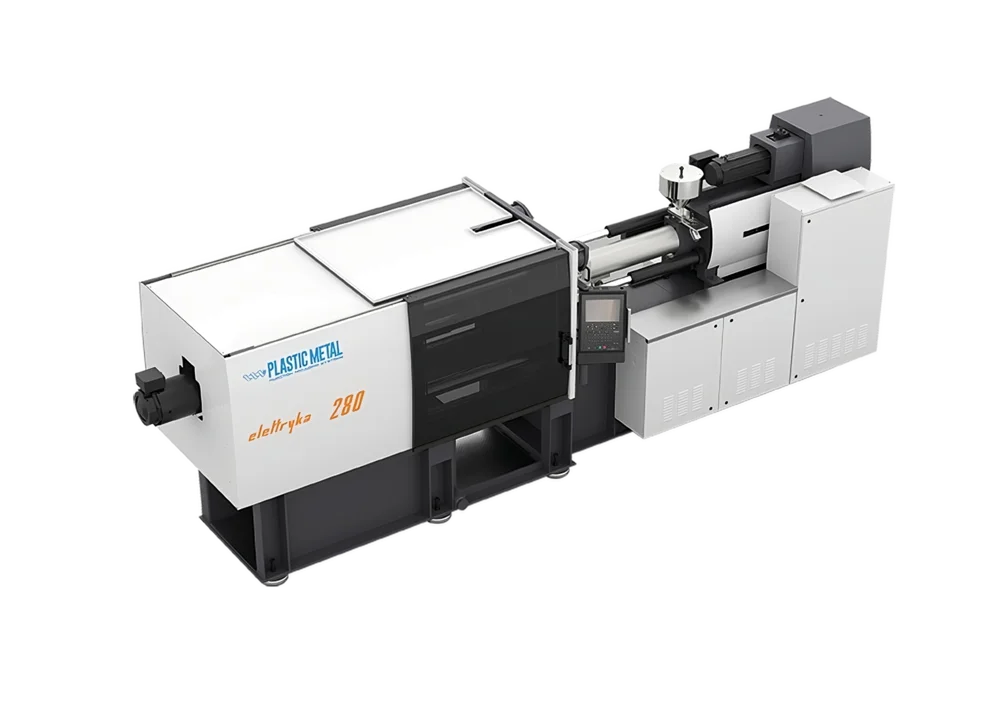

Hybrid multi-injection molding machine

Multi-Injection

The MULTIPOWER technology also applies to multi-injection machines to support an increasingly sophisticated and demanding market.

MULTI-INJECTION is the line of hybrid and electric injection molding machines that allows you to apply multiple injections according to different molding requirements. The multi-injection technology is revolutionizing the traditional molding also because it helps reduce the production phases, optimizing time and costs. Co-injection, over-molding, sequential injection, molding of bi-color or bi-material, and any other special applications required by the most advanced technologies are applicable to all the Plastic Metal machines.

The different installed injections can always work in an autonomous and independent manner, ensuring maximum flexibility and adaptability to the production needs.

Desideri saperne di più su come i nostri prodotti possono migliorare la tua produzione?

Richiedi maggiori informazioni oggi stesso e scopri come Plastic Metal può aiutarti a raggiungere risultati straordinari.

Multi-injection molding machine

MULTI INJECTION

The double or triple-injection machine range has been developed for the specific needs of the multi- component and bi-color molding, in-mould assembling and over-molding.

Available in Multipower (hybrid technology), the multi-injection machines are designed according to the specific needs of the client and the molding itself.

The application of complements such as the rotary table allows simultaneous injection of two or more plastic material, or the application of specific nozzles for the co-injection thus the sequential injection of two materials through the same nozzle. According to the molding requirements it is possible to position a second or a third injection unit in different positions: parallel to the main group, vertical, oblique, or on a self-supported base on the opposite side of the operator.

Advantages of Multi-Injection

Maximum system reliability

5 point toggle clamping system

Maximum flexibility for high speed

Guaranteed energy saving

Special and customized productions

Molding types

This technique is characterized by the use of one or more inserts inside the mold. After completing the injection of the first material, the inserts in the mold are moved so as to create, inside the cavity, the space required for the injection of the second material.

The technique of CO-INJECTION finds application in the production of articles made with different materials. The adoption of this production process may have technical reasons (materials with different chemical- physical characteristics) or economic (use of valuable materials externally and cheaper or recycle materials internally). This technique involves the injection of the two materials in sequence, through the same nozzle.

Plastic Metal designs and manufactures special applications according to customer requirements. For example, for the production of ski boots and in- line skates, Plastic Metal has created machines with vertical clamping unit and two horizontal injection units with the possibility of annexing a third horizontal injection unit. This type of machine allows the rotary sequential molding.

It is an over-molding technique that uses a rotating plate (hydraulic or electric). On this plate, mounted on the moving platen of the machine in a vertical position, is fixed one half of the mold. After the injection of the first material through the main injection unit, the rotating plate moves the mold and places it in a position that allows the injection of the second material.

The technique of the BI-INJECTION is characterized by the injection of two different materials, at the same time, within the same cavity but through two different nozzles. The final product obtained with this technique depends, basically, both from the technical characteristics and the configuration of the machine, and on the design of the mold.

Il prodotto finale ottenuto con questa tecnica dipende, fondamentalmente, sia dalle caratteristiche tecniche e dalla configurazione della macchina, sia dalle modalità costruttive dello stampo.

REQUEST MORE INFO

Fill in the form, we’ll answer as soon as possible.