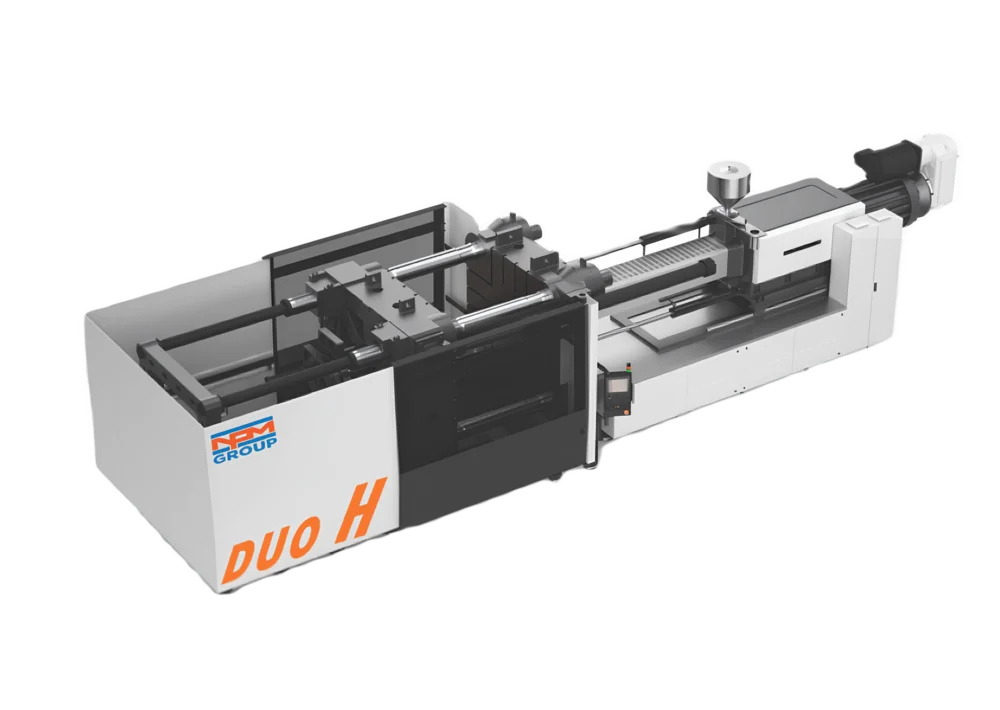

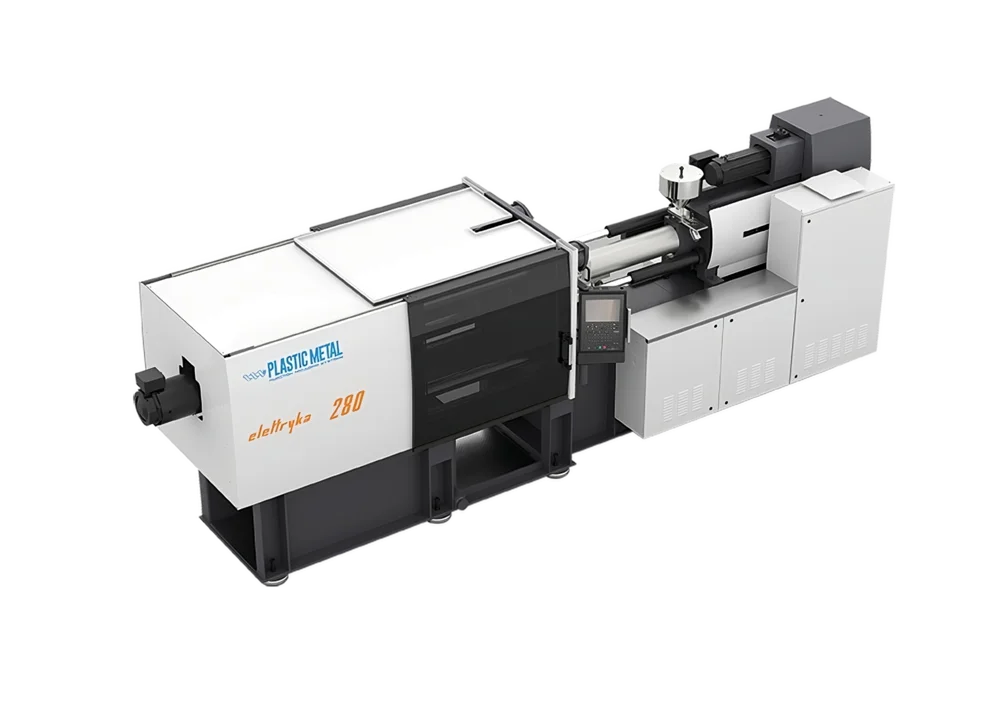

Preforms production system

Multipower I-PET

Complete systems for the production of PET preforms

Reliable and user friendly, excellent price-productivity ratio, energy savings and reduced production costs, high product quality standard.

Desideri saperne di più su come i nostri prodotti possono migliorare la tua produzione?

Richiedi maggiori informazioni oggi stesso e scopri come Plastic Metal può aiutarti a raggiungere risultati straordinari.

Advantages of I-Pet

Maximum system reliability

Guaranteed energy savings

Two-platen clamping system

Accumulators for injection unit (H version)

User friendly interface, simple and intuitive

Wireless connection for on-line assistance

The movements

The injection unit is based on the technology of a rotary piston, hydraulically balanced under accumulators, without any thrust bearings. This is the most complex movement of the machine and it determines the quality of the moulded product. The axis control, realized by a close-loop control servo valve (Moog), ensures the optimization of all the conditions required even in the most sophisticated moulding processes. A very small size motor, coupled to a pump with internal gear, provides for the recharge of the accumulators and creates the optimum conditions of use. The switching on/off of the pump is controlled by an inverter that shuts off the motor once the required level has been reached, thus minimizing power consumption and maximizing the system efficiency. This procedure allows to obtain maximum speed performance otherwise impossible, while maintaining precise and constant control on speed and pressure.

Therefore the several advantages of this application are:

- reliability

- high precision

- high performance

- considerable energy savings, that come from the fact that the motor is automatically switched-off (thus reducing consumption to zero) once the accumulator is full.

The approaching movement of the injection unit is executed by two hydraulic cylinders that allow the injection unit to maintain the correct position during the whole moulding cycle. Once the system is under pressure, a non-return valve prevents the carriage retract keeping the nozzle in its position without wasting energy.

The central ejection is actuated by a 3-piston electric drive, specially developed for this type of machine. It ensures a high ejection force at the beginning of the stroke and a high speed during the remaining movement, as well as greater flexibility and ease when hooking up the ejection rods of the mould.

The screw rotation, operated by a brushless water cooled electric motor, is controlled by an inverter associated with a high performance reduction system that ensures high torque and resistance to the highest mechanical stress. The control of the movement through inverter allows to use only the energy required by the plasticizing screw during the dosing phase. All machine movements can be operated simultaneously.

The new design of the operator interface, mixed with a 12-inch video touch and push buttons for manual operation, makes man-machine interface user friendly, simple and intuitive. More than 60 video pages dedicated to the setting of all process parameters. Additional summary pages allow the operator to keep track of all basic parameters of the moulding cycle. Several test and diagnostics pages help the operator to instantly verify any machine operations and components. Other pages show real-time graphs of machine movements. The operator can switch from page to page without going back to the menu. The software is translated into over 15 languages, using the specific characters of each language for easy and quick understanding by the operator.

The clamping system is based on a five-point double toggle with steel links and special bronze bushings. The lubrication system is cyclic and programmable by points, with safety devices that allow constant monitoring. The moving platen is supported by adjustable sliding blocks to ensure less friction and complete safety of the mould.

The clamp closing/opening movement is operated by an electromechanical axis based on the technology of a screw ball. The lubrication of the screw ball is entrusted to a special pump developed specifically for this application, and completely independent of the lubrication of the links. The rotation of the system is provided by a brushless motor specially designed with hollow shaft installed directly on axis to the system, controlled by an inverter. This motor, developed in cooperation with Moog, provides the system with torque and speed that result in a very fast and precise mould movement, perfectly controlled in acceleration and breaking. At the same time it allows an excellent control of “mould safe”. The motor is water cooled and constantly monitored by temperature sensors that ensure the optimal temperature throughout the system.

REQUEST MORE INFO

Fill in the form, we’ll answer as soon as possible.