Customize systems for high-level performance

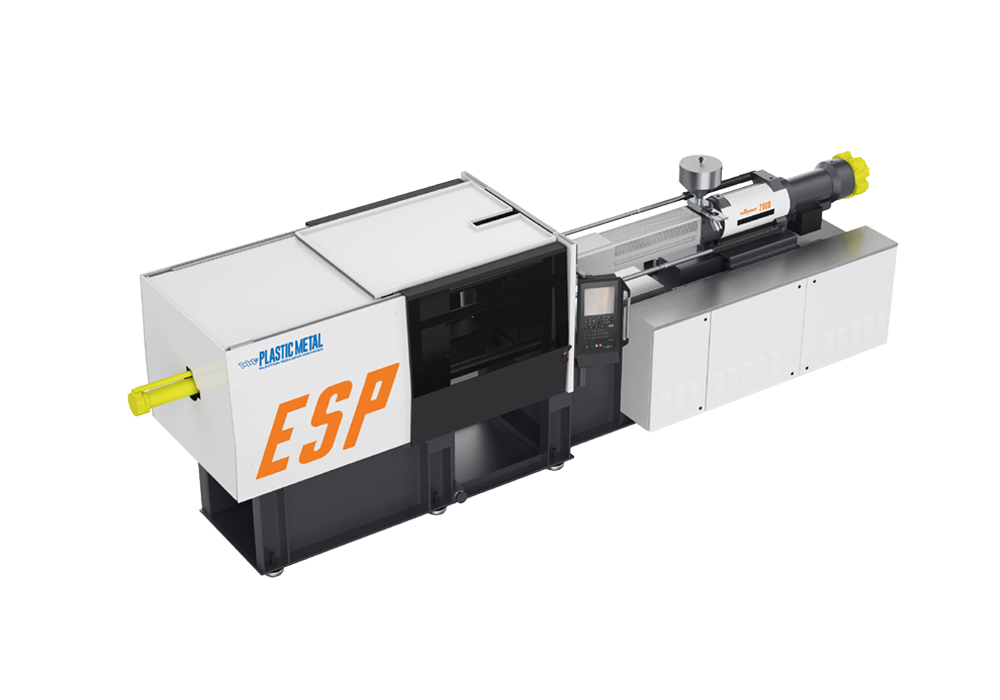

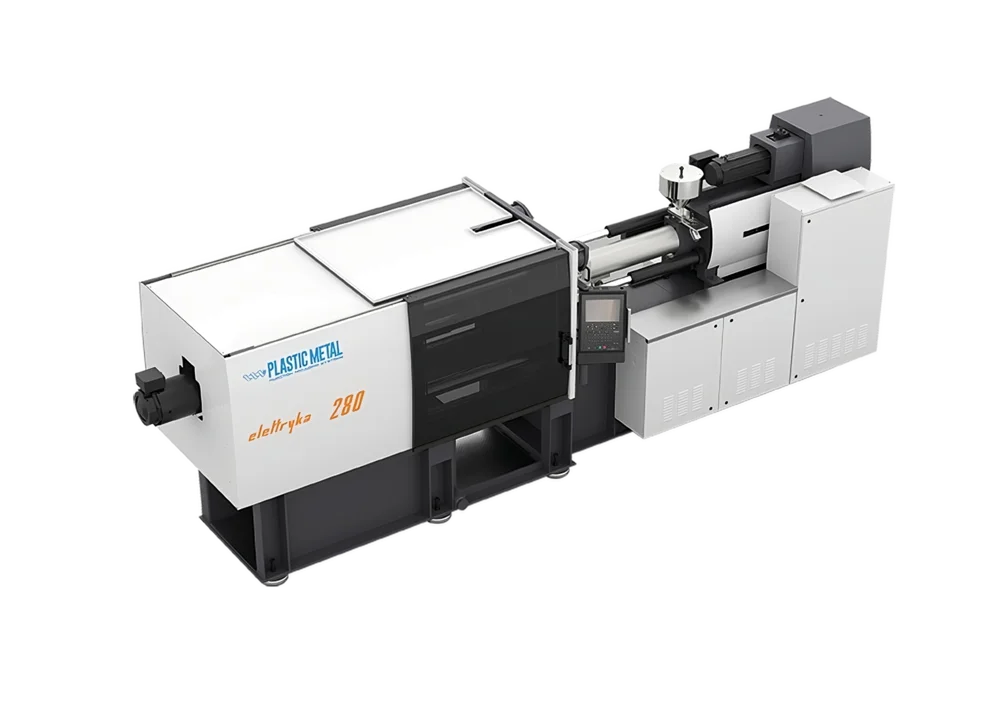

Plastic Metal company structure allows the customer to develop a unique project in synergy, to stand out in the market and ensure high-quality injection moulding.

What are the advantages of a customize system and why choose Plastic Metal?

A customer is satisfied when he can explain his needs and find out a product that fulfilled his necessity, a customized product.

From the planning to the installation, Plastic Metal is always in a constant communication with the clients to realize a customize moulding islands suitable for their product to be molded.

To do this, an agile and flexible structure is needed, which promptly responds to the customer’s questions, and which can propose alternative solutions as the project evolves “from the beginning to the final test”.

It also requires the full availability of the customer and the ability to analyze, re-write their expectations and needs according to the existing technology, with a view to transparent collaboration.

These are starting points to realize an ambitious and unique plant that allows the customer not only to realize its products with an excellent quality, (that is required from an injection moulding machine in the automotive sector), but also to have a highly versatile plant for his various needs.

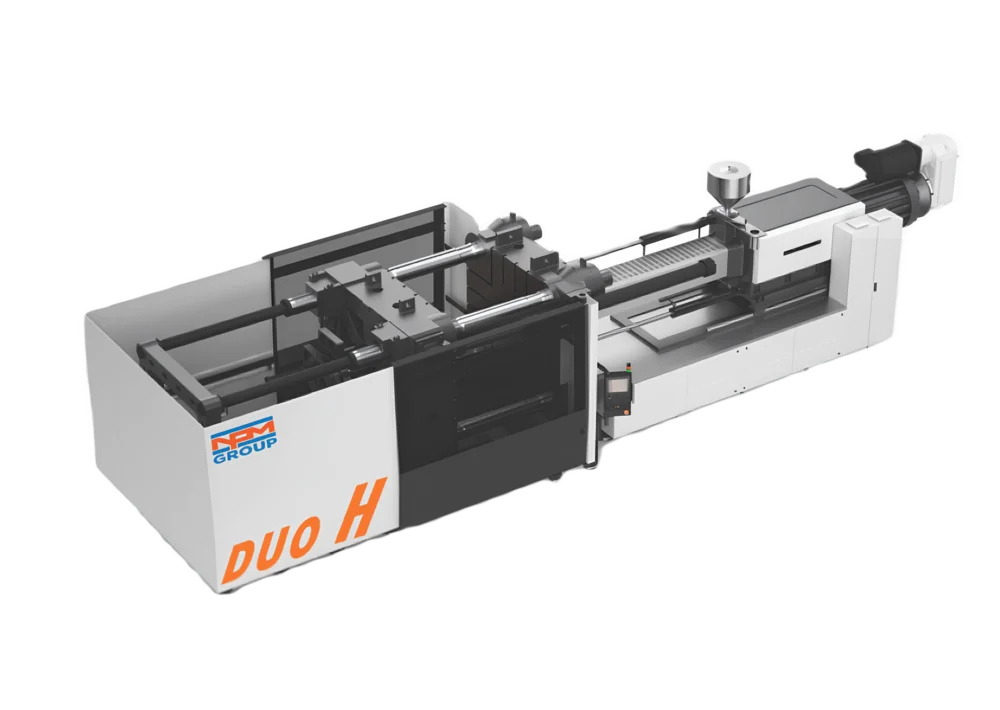

ELMANN srl: The automotive injection moulding machine of 1800 ton and 6 injection units

Elmann srl, a leading Italian company in the moulding of the automotive sector -especially in car headlight – turned to Plastic Metal for a new injection moulding plant.

Until a few years ago, to realize a headlight, it was necessary to have several moulding injection machines that molded different pieces, which would then be assembled.

But Elmann Team had a more ambitious goal: to have a single, flexible machine to satisfy each of its customers with the same injection moulding machine.

Plastic Metal was able to find out a specific solution to please Elmann needs, creating 1800-ton machine with 6 injection units:

- two independent injections units on the injection group side, with a hole of the fixed platen in an oval shape allowing free movements for each independent injection units.

- two independent injection units in vertical position, also with independent movements.

- one injection unit at the rear of the extractor, which rises during the injection.

- a smaller injection unit positioned on the opposite side of the operator.

Each unit works freely, and they can be individually planned or in sequence, depending on the type of moulding.

Even this system has a MULTIPOWER technology for a low energy consumption and a maximum moulding flexibility.

Do you want more information on this article?

Fill out and send the form below, our specialists will contact you as soon as possible.